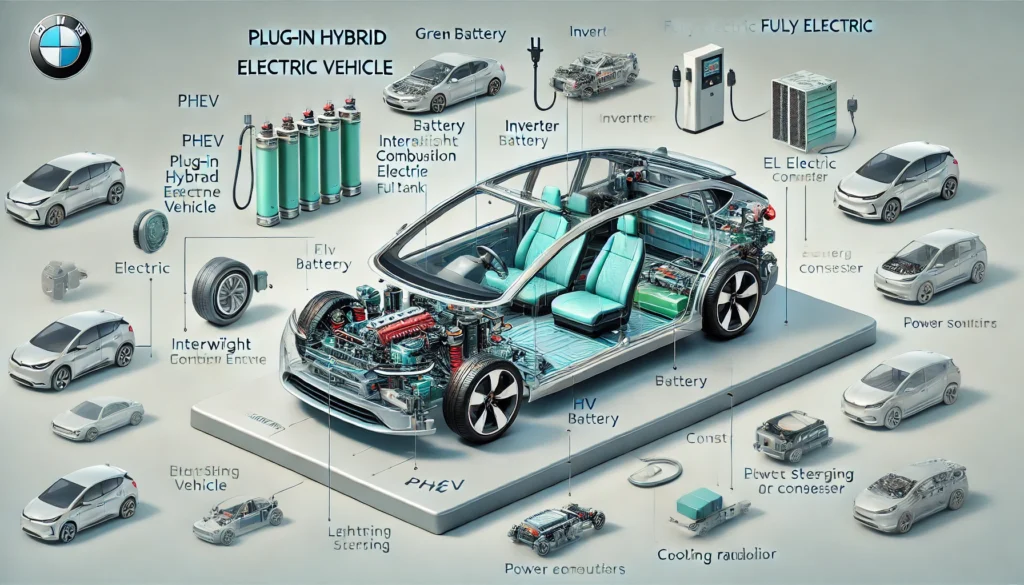

🔌 Plug-in Hybrid vs. Fully Electric Cars: A Technical Comparison

Electric mobility is reshaping the automotive industry, offering sustainable alternatives to traditional internal combustion engines. Two of the most prominent technologies are the Plug-in Hybrid Electric Vehicle (PHEV) and the Battery Electric Vehicle (BEV). While both reduce emissions and rely on electric power, they use distinct architectures and serve different user needs. In this post, we’ll break down the engineering behind each system, using a clear, labeled infographic to explore their main components. ⚡ 1️⃣ Plug-in Hybrid Electric Vehicle (PHEV) A PHEV combines the best of both worlds: an internal combustion engine (ICE) and an electric drivetrain with a rechargeable battery pack. This configuration allows short-distance electric driving while retaining the flexibility of a gasoline engine for longer trips. 🔍 Key Components: ✅ Advantages: ⚠️ Drawbacks: ⚡ 2️⃣ Battery Electric Vehicle (BEV) A BEV is fully electric, with no gasoline engine. It relies entirely on large-capacity batteries to power an electric motor. It produces zero tailpipe emissions, representing the cleanest option for personal transport. 🔍 Key Components: ✅ Advantages: ⚠️ Drawbacks: 🔎 Engineering Comparison Feature PHEV BEV Power Sources Gasoline + Electric Fully Electric Battery Size Smaller (10–20 kWh typical) Larger (40–100+ kWh) Range Electric-only + gasoline range Electric-only Emissions Low, but not zero Zero tailpipe emissions Complexity High (dual systems) Simpler (all-electric) Refueling Time Fast with gasoline, slower when charging Charging-dependent 🛠️ Conclusion Plug-in hybrids and battery electric vehicles both play vital roles in the transition toward sustainable transport. PHEVs offer a transitional technology ideal for drivers needing long-range flexibility, while BEVs represent the ultimate goal of a fully decarbonized transport system. As battery technology improves and charging networks expand, BEVs will likely dominate the market. But today, both technologies help reduce fuel consumption, lower emissions, and pave the way for a cleaner future. 📌 Suggested Reading