About Course

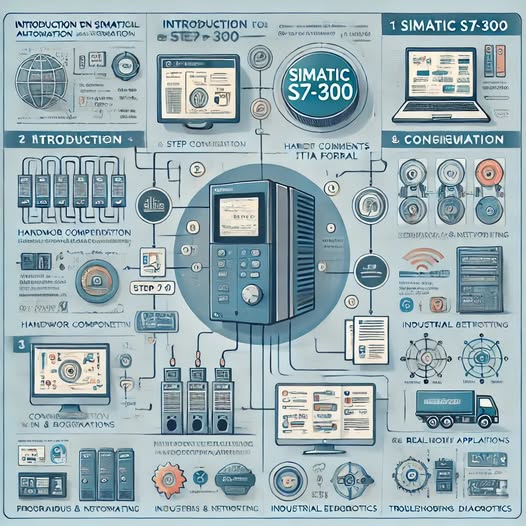

Course Plan: Simatic S7-300 Automation System

🔹 Code: 11004-PEM

Introduction

The Simatic S7-300 is a Programmable Logic Controller (PLC) from Siemens, widely used in industrial automation systems. This course provides hands-on training to understand the fundamentals of programming and using this system for factory automation and process control.

Course Content

1️⃣ Introduction to Industrial Automation & S7-300

-

Concepts of Automation and its importance in industry

-

Introduction to Siemens Simatic S7-300

-

System Components: CPU, I/O modules, communication modules

-

Overview of the STEP 7 Programming Environment

2️⃣ Programming S7-300 Using STEP 7

-

Basics of Ladder Logic (LAD) Programming

-

Using Statement List (STL) and Function Block Diagram (FBD)

-

Working with Variables and Memory Management

-

Writing and Uploading a PLC Program

3️⃣ Signal Processing & Process Control

-

Configuring Digital & Analog Input/Output Signals

-

Motor & Valve Control Techniques

-

Using Timers & Counters in PLC Programming

4️⃣ Communication & Networking

-

PROFIBUS & Industrial Ethernet Protocols

-

Configuring Communication Between Multiple PLCs

-

Reading & Writing Data Over Networks

5️⃣ Fault Diagnosis & Maintenance

-

Using STEP 7 Diagnostics for Troubleshooting

-

Handling Hardware & Software Errors

-

Maintenance Strategies & Performance Optimization

6️⃣ Practical Projects & Real-World Applications

-

Factory Control System Design

-

Automating an Assembly Line Using S7-300

-

Pump & Valve Control System Implementation

Course Objectives

✅ Understand the components of the Simatic S7-300 system and how to program it

✅ Develop PLC control programs using STEP 7

✅ Learn communication techniques between PLC units

✅ Diagnose issues and perform maintenance effectively

Target Audience

👷 Automation & Industrial Control Engineers

🔧 Technicians & Factory Operators

🎓 Students & Researchers in Electrical Engineering

Course Duration & Certification

📅 Duration: 30-40 Training Hours

📜 Certification: Certificate of Completion + Practical Project

🚀 Ready to Master Industrial Automation?

Simatic S7-300 Automation System Overview

🔹 What is Simatic S7-300?

The Simatic S7-300 is a programmable logic controller (PLC) from Siemens, designed for medium to large-scale industrial automation applications. It is used in factories and production lines to enhance process control and productivity.

⚙️ Key Features:

-

🔌 Modular Design: Easily expandable with additional modules.

-

📊 High Performance: Fast response time and precise control.

-

🌐 Industrial Networking Support: Compatible with PROFIBUS & Industrial Ethernet.

-

🔄 Easy Programming: Supports TIA Portal & STEP 7.

-

🛠️ Integration: Works with HMI & SCADA systems.

🎯 Applications:

🏭 Factory Production Lines & Machine Control

🚆 Transportation & Packaging Systems

⚙️ Heavy & Chemical Industries for Process Monitoring

Student Ratings & Reviews