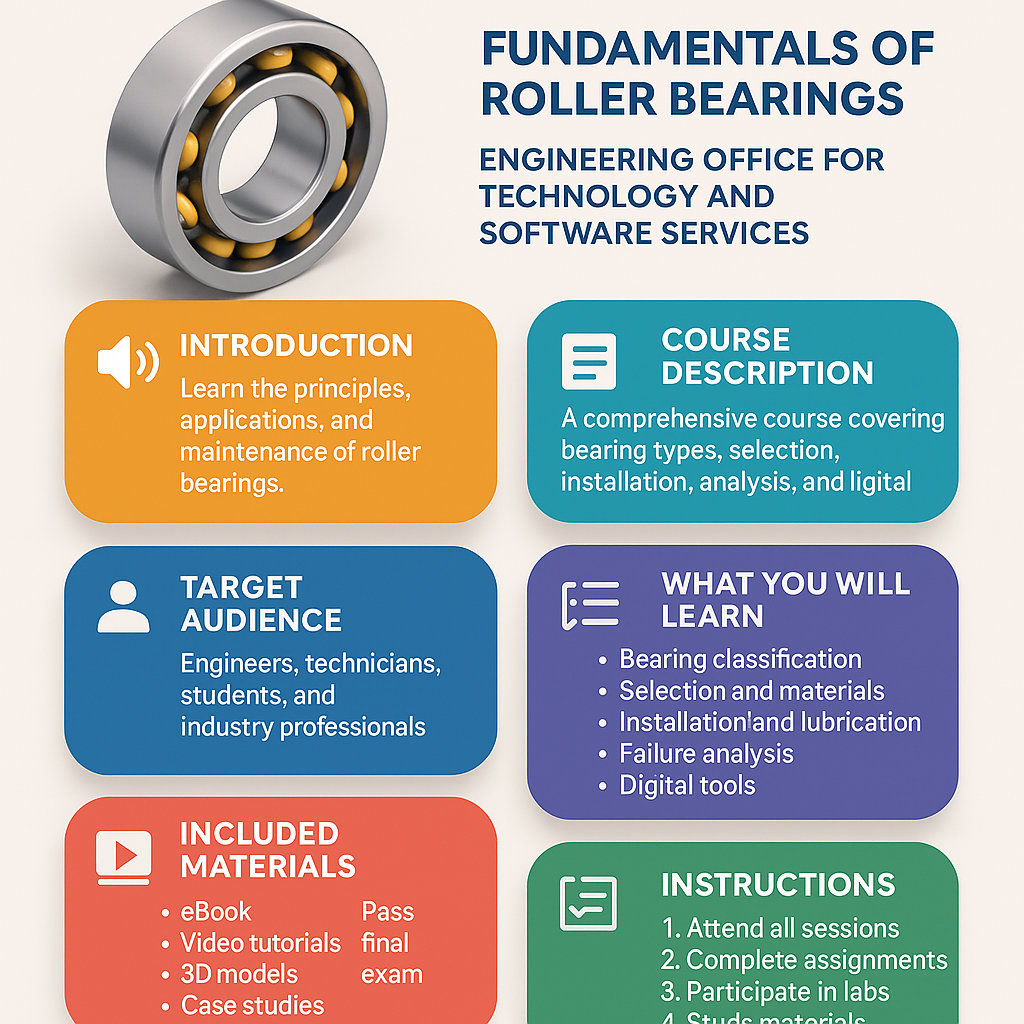

Roller bearings are crucial mechanical components designed to facilitate motion and minimize friction between rotating shafts and stationary parts. This course provides a comprehensive foundation in roller bearing technology, enabling learners to understand their construction, operation, and applications across various industries.

This course explores the fundamental principles of roller bearings, covering their types, working mechanisms, materials, lubrication methods, failure modes, and practical considerations in design and maintenance. Emphasis is placed on both theoretical understanding and real-world application.

To develop a solid grasp of roller bearing principles and types.

To analyze the function and selection criteria of roller bearings.

To understand installation, maintenance, and troubleshooting methods.

To examine common causes of failure and preventive strategies.

Introduction to Bearings

Historical evolution

Classification of bearings

Types of Roller Bearings

Cylindrical, spherical, tapered, and needle roller bearings

Design features and use cases

Principles of Operation

Load distribution

Friction reduction mechanisms

Materials and Manufacturing

Bearing steels and alternatives

Quality control processes

Lubrication Techniques

Types of lubricants

Lubrication systems and regimes

Failure Analysis

Wear, fatigue, corrosion, and misalignment

Diagnostic tools and methodologies

Selection and Sizing

Load and speed calculations

Life expectancy assessment

Installation & Maintenance

Mounting/dismounting procedures

Inspection and condition monitoring

Classification and identification of roller bearings

Operational principles and core functions

Lubrication and maintenance best practices

Failure modes and troubleshooting techniques

Criteria for bearing selection and application

Mechanical engineering students

Maintenance engineers and technicians

Industry professionals in automotive, manufacturing, and energy sectors

Technical trainers and educators

Illustrated course handbook (PDF)

Interactive 3D animations and schematics

Real-world case studies

Practice quizzes and assignments

Instructor-led lectures and seminars

Virtual lab demonstrations

Group discussions and problem-solving sessions

Hands-on exercises with bearing models

Total duration: 16 hours (4 sessions, 4 hours each)

Blended learning (on-campus and online options)

Synchronous and asynchronous content

Access to online resource platform

Upon completion, participants will:

Demonstrate understanding of roller bearing technologies

Select appropriate bearing types for specific applications

Diagnose and prevent bearing failures

Implement maintenance procedures for optimal bearing performance