🔌 Plug-in Hybrid vs. Fully Electric Cars: A Technical Comparison

Electric mobility is reshaping the automotive industry, offering sustainable alternatives to traditional internal combustion engines. Two of the most prominent technologies are the Plug-in Hybrid Electric Vehicle (PHEV) and the Battery Electric Vehicle (BEV). While both reduce emissions and rely on electric power, they use distinct architectures and serve different user needs.

In this post, we’ll break down the engineering behind each system, using a clear, labeled infographic to explore their main components.

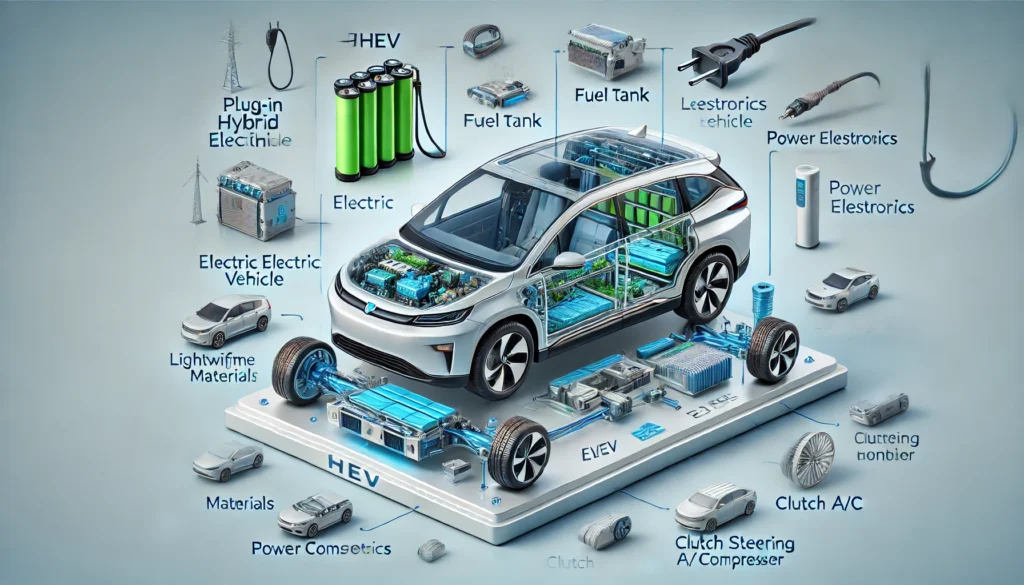

⚡ 1️⃣ Plug-in Hybrid Electric Vehicle (PHEV)

A PHEV combines the best of both worlds: an internal combustion engine (ICE) and an electric drivetrain with a rechargeable battery pack. This configuration allows short-distance electric driving while retaining the flexibility of a gasoline engine for longer trips.

🔍 Key Components:

- Battery (High-Capacity): Positioned at the rear, stores energy for electric-only driving. Typically smaller than a BEV’s battery.

- Fuel Storage (Gas Tank): Supports long-range travel without charging.

- Internal Combustion Engine (ICE): Works alone or with the electric motor.

- Power Electronics: Manages energy flow between battery and motor.

- Lightweight Materials: Reduce overall weight to improve efficiency.

- Charging Plug: Enables external charging for the battery.

✅ Advantages:

- Eliminates range anxiety thanks to gasoline backup.

- Can drive in electric-only mode for daily commutes.

- Flexible for regions with limited charging infrastructure.

⚠️ Drawbacks:

- More complex mechanical design.

- Heavier than standard hybrids or BEVs.

- Still reliant on fossil fuels for long trips.

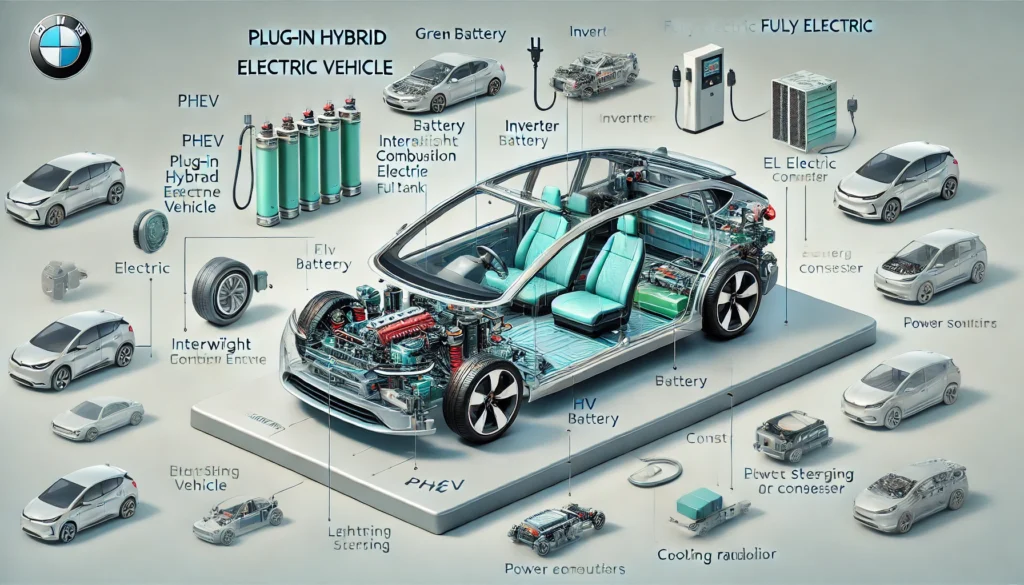

⚡ 2️⃣ Battery Electric Vehicle (BEV)

A BEV is fully electric, with no gasoline engine. It relies entirely on large-capacity batteries to power an electric motor. It produces zero tailpipe emissions, representing the cleanest option for personal transport.

🔍 Key Components:

- HV-Battery Pack: Runs along the vehicle floor for low center of gravity.

- Inverter: Converts DC from the battery into AC for the motor.

- DC/DC Converter: Steps down high-voltage power to 12V systems.

- Electric Motor: Drives the wheels with instant torque.

- Plug-in Socket: Connects to external chargers.

- Additional Radiator: Manages thermal loads.

- Clutch Actuation, EL Steering Pump, EL A/C Compressor: Electrically driven accessories replacing traditional belt-driven components.

✅ Advantages:

- Zero tailpipe emissions.

- Lower operating and maintenance costs.

- Instant torque and smooth driving experience.

⚠️ Drawbacks:

- Range limited by battery capacity.

- Dependent on charging infrastructure.

- Longer refueling (charging) times compared to gasoline.

🔎 Engineering Comparison

| Feature | PHEV | BEV |

|---|---|---|

| Power Sources | Gasoline + Electric | Fully Electric |

| Battery Size | Smaller (10–20 kWh typical) | Larger (40–100+ kWh) |

| Range | Electric-only + gasoline range | Electric-only |

| Emissions | Low, but not zero | Zero tailpipe emissions |

| Complexity | High (dual systems) | Simpler (all-electric) |

| Refueling Time | Fast with gasoline, slower when charging | Charging-dependent |

🛠️ Conclusion

Plug-in hybrids and battery electric vehicles both play vital roles in the transition toward sustainable transport. PHEVs offer a transitional technology ideal for drivers needing long-range flexibility, while BEVs represent the ultimate goal of a fully decarbonized transport system.

As battery technology improves and charging networks expand, BEVs will likely dominate the market. But today, both technologies help reduce fuel consumption, lower emissions, and pave the way for a cleaner future.

📌 Suggested Reading

- How Electric Vehicle Batteries Work

- The Future of Charging Infrastructure

- Hybrid vs. Electric: Which Is Right for You?