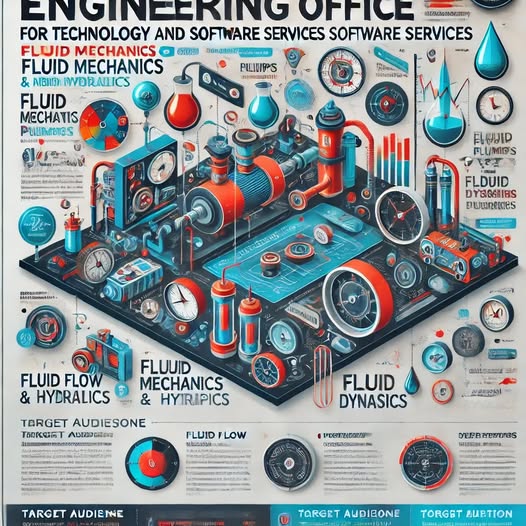

Engineering Office for Technology and Software Services Academy

This course delivers a comprehensive foundation in fluid mechanics and hydraulics, focusing on analyzing fluid flow, pressure losses, and pump system design. It’s tailored for engineers and students involved in designing hydraulic and fluid-based systems.

Mechanical Engineers

Civil Engineers

Hydraulic System Designers

Engineering Students (Mechanical, Civil, Energy, Hydraulics)

5 Weeks (15 sessions, 3 sessions/week)

2 hours per session

Total: 30 Hours

Understand the physical behavior and fundamentals of fluid flow

Analyze pressure distribution and velocity in pipelines and pumps

Design and optimize hydraulic systems using real-world applications

Utilize simulation tools to model fluid dynamics in practical systems

What is a fluid? Physical properties of fluids

Pressure in fluids: hydrostatics and manometry

Bernoulli’s Equation and energy conservation

Applications of Bernoulli in pipes, nozzles, and open channels

Flow types: Viscous vs. Inviscid, Laminar vs. Turbulent

Reynolds number and flow regimes

Equations of motion in fluids

Forces on submerged and moving bodies (lift and drag)

Internal flow in pipelines

Pressure losses due to friction

Darcy-Weisbach Equation and Moody chart

Minor losses in bends, valves, and fittings

Series and parallel pipe systems

Types of pumps: Centrifugal, Positive Displacement

Pump selection and system head calculations

Pump performance curves and system curves

Complex hydraulic network analysis

Simulation using ANSYS Fluent or SolidWorks Flow Simulation

Case studies:

Water distribution networks

Cooling systems for machinery

Hydraulic power transmission

Final project: Design & analyze a complete hydraulic system

Analyze flow in a branched piping network

Design and simulate a water pump system

Industrial fluid flow simulation using software

Optimize cooling flow in a mechanical system

Computer with simulation-capable specs

ANSYS Fluent, SolidWorks Flow Simulation, or equivalent software

Scientific calculator for hydraulic equations

Certificate of Completion will be awarded.

By the end of this course, participants will:

Master fluid mechanics principles

Analyze and design fluid and hydraulic systems

Use simulation tools to model real-life hydraulic scenarios

Solve flow-related challenges in industry-level projects