About Course

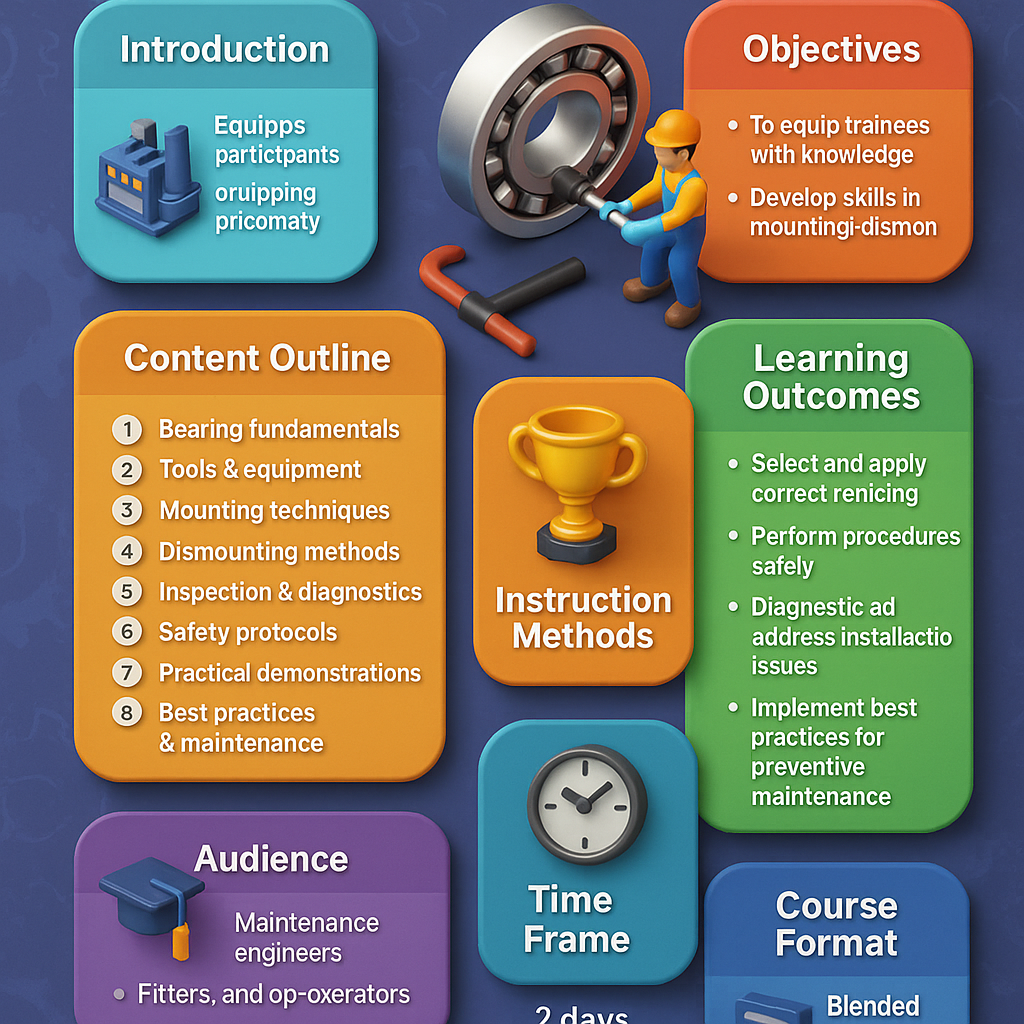

Mounting & Dismounting of Roller Bearing

Code: 2076-MECH

(Professional Training Course)

Introduction 🏭

This course provides a comprehensive introduction to the principles, best practices, and techniques involved in the correct mounting and dismounting of roller bearings, with an emphasis on safety, precision, and machinery reliability.

Description 🔧

Participants will explore detailed methodologies for the handling, installation, and removal of various types of roller bearings. The course integrates real-world scenarios, interactive demonstrations, and evidence-based procedures to minimize damage and extend equipment life.

Objectives 🎯

- To equip trainees with essential knowledge of bearing types and applications.

- To develop practical skills in the safe and correct mounting/dismounting of roller bearings.

- To enhance troubleshooting abilities and preventive maintenance practices.

Outlines in Detail 📋

- Bearing Fundamentals: Types, construction, and applications

- Tools & Equipment: Selection and use of tools for mounting/dismounting

- Mounting Techniques: Mechanical, hydraulic, and thermal methods

- Dismounting Methods: Safe removal procedures and risk mitigation

- Inspection & Diagnostics: Identifying common failures and wear

- Safety Protocols: PPE, work environment, and handling precautions

- Practical Demonstrations: Hands-on exercises and troubleshooting

- Best Practices & Maintenance: Recordkeeping and reliability optimization

What You Will Learn 📘

- Correct procedures for mounting and dismounting different roller bearing types

- Effective use of tools and technology in bearing handling

- Preventive maintenance strategies to enhance machinery life

- Analysis of bearing failures and corrective actions

Target Audience 🎓

- Maintenance engineers and technicians

- Mechanical fitters and supervisors

- Plant operators and reliability specialists

- Vocational students in mechanical or industrial engineering

Materials 🛠️

- Comprehensive course handbook (digital & print)

- Manufacturer technical datasheets

- Bearing mounting/dismounting toolkits

- Personal protective equipment (PPE) for practical sessions

Instruction Methods 👨🏫

- Interactive lectures and multimedia presentations

- Practical hands-on workshops

- Real-world case studies and group discussions

- Quizzes and knowledge assessments

Time Frame ⏳

- Total duration: 2 days (16 hours)

- Day 1: Theory & Demonstration (8 hours)

- Day 2: Hands-on Practice & Assessment (8 hours)

Course Format 🗂️

- Blended learning (in-person and online components)

- Modular structure for flexible participation

- Certificate of completion awarded after final assessment

Learning Outcomes 🏆

Upon completion, participants will be able to:

- Select and apply the correct tools and methods for mounting/dismounting roller bearings

- Perform procedures safely, minimizing equipment damage and personal injury

- Diagnose and address common bearing installation issues

- Implement best practices for preventive maintenance