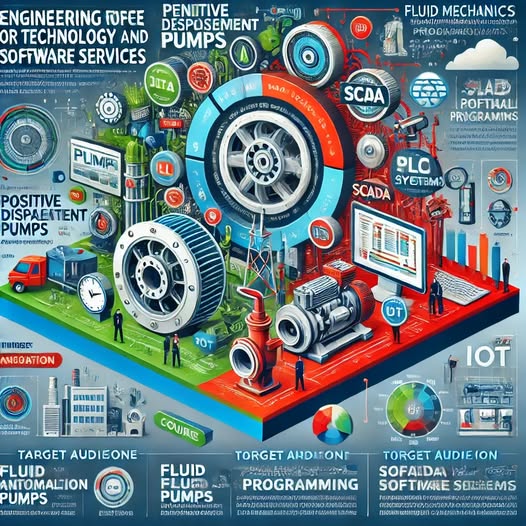

About Course

Pumping and Software Related Technologies

Course Code: 2055-MECH

🏢 Engineering Office for Technology and Software Services Academy

🎓 Course Title: Pumping and Software Related Technologies

🎯 Target Audience

-

Mechanical and Electrical Engineers

-

Industrial Automation & Control Professionals

-

Software Developers in Industrial Engineering

-

Engineering Students and Researchers (Mechanical/Electrical)

🕒 Duration

-

5 Weeks

-

10 Sessions (2 sessions/week)

-

1.5 hours per session

-

Total: 15 Hours

✅ Course Objectives

-

Understand the fundamentals of pumping systems

-

Learn pump selection, design, and automation

-

Integrate pumps with software platforms (CFD, HMI, PLC, SCADA, IoT)

-

Analyze pump performance and improve system efficiency

-

Gain hands-on experience in real industrial scenarios

📚 Course Modules

🔹 Module 1: Introduction to Pumping Technologies

-

Types of Pumps: Centrifugal, Positive Displacement

-

Pump components and system architecture

-

Basics of Fluid Mechanics for pumping systems

-

Industrial applications of pumps

🔹 Module 2: Pump Selection and Design

-

Criteria for choosing the right pump

-

Calculations: flow rate, head, pressure

-

Understanding pump performance curves

-

Practical examples of pump sizing and selection

🔹 Module 3: Pump Control and Automation

-

Variable Frequency Drives (VFDs) for speed control

-

Automation using PLCs and SCADA systems

-

Sensor integration and real-time monitoring

-

Hands-on automation case studies

🔹 Module 4: Pump Maintenance and Repair

-

Fault diagnosis and early failure detection

-

Preventive Maintenance strategies

-

Repairing and replacing major components

-

Practical tasks in predictive maintenance

🔹 Module 5: Pumping-Related Software Tools

-

Using CFD (ANSYS) for flow simulation

-

HMI (Wonderware, Ignition) for pump interfaces

-

Remote control via SCADA systems

-

Hands-on use of software in simulated environments

🔹 Module 6: Programming and Industrial Control

-

Programming PLCs (Siemens TIA Portal, Allen Bradley Studio 5000)

-

System integration with industrial devices

-

IoT-based monitoring and alert systems

-

Real use cases of programmable pump control

🔹 Module 7: Data Analysis and Performance Optimization

-

Collecting and analyzing pump performance data

-

Predictive Maintenance using AI & ML techniques

-

Enhancing energy efficiency in pump systems

-

Practical optimization workflows

🔹 Module 8: Safety and Pump Protection

-

Industrial safety systems for pumps

-

Dry run protection and overload safeguards

-

Vibration and noise control strategies

-

Applied examples of protective configurations

🔹 Module 9: Capstone Projects and Real-World Applications

-

Designing and implementing a complete pump control system

-

PLC programming for automated pump stations

-

Data analysis and visualization for system efficiency

-

Final graduation project and real-world applications

💻 Tools and Software Required

-

MATLAB & ANSYS CFD – Fluid simulation

-

Siemens TIA Portal / Allen Bradley Studio 5000 – PLC Programming

-

Wonderware, Ignition – HMI/SCADA Systems

-

IoT Platforms – Remote Monitoring & Integration

-

Real industrial case studies and hands-on simulations

🎓 Prerequisites

-

Basic understanding of physics and fluid mechanics

-

Prior exposure to industrial control or basic programming

-

Introductory experience with hydraulic or electrical systems is recommended

🏅 Certification & Outcomes

-

Certificate of Completion

-

Real project experience with simulation and control tools

-

Industry-aligned skills in pumping systems, automation, and performance analysis

Course Content

Pumping and Software Related Technologies

Student Ratings & Reviews